- Building, Maintenance & Repair of Kitchen Exhaust Systems

- Maintenance of Kitchen Exhaust System

- Repair of Kitchen Exhaust System

- Chemical Degreasing of Kitchen Exhaust System

- Fabrication and Installation of Stainless Steel / Aluminum Kitchen Exhaust Hood

- Wet Chemical Suppression Systems

- Electrostatic Air Cleaners & UV-C Emitters

- Kitchen Exhaust Fans & Variable Speed Drives (VSD)

- Fabrication of Electrical Control Panels

- Submissions to FSSD (Fire Safety & Shelter Department)

Building of Kitchen Exhaust System

We provide complete design and construction of commercial kitchen exhaust systems tailored to your kitchen’s layout, cooking intensity, and regulatory requirements. Our systems include exhaust hoods, ducting, fans, filtration units, and control panels—engineered for optimal airflow, grease capture, and heat extraction. Every installation is done in compliance with Singapore’s SFA and FSSD standards, ensuring safe operation and long-term durability. Whether it’s a new kitchen or a renovation, we deliver turnkey solutions that meet both functional and fire safety needs.

Maintenance of Kitchen Exhaust System

Regular maintenance is essential to keep your kitchen exhaust system running efficiently and safely. Our maintenance service includes thorough inspection of hoods, ducts, fans, filters, and control panels. We clean grease buildup, check for wear and tear, and ensure all components are functioning properly. This proactive approach helps prevent fire hazards, improves air quality, and extends the lifespan of your equipment. We offer flexible maintenance schedules—monthly, quarterly, or annually—based on your kitchen’s usage and compliance needs.

Repair of Kitchen Exhaust System

When your exhaust system faces issues such as reduced airflow, motor failure, or damaged ducting, our skilled technicians provide fast and effective repair services. We diagnose problems accurately and replace or fix faulty components including fans, motors, control panels, and filters. Our goal is to minimize downtime and restore full functionality with minimal disruption to your kitchen operations. Emergency repair support is also available for urgent cases, ensuring your kitchen remains safe and compliant.

Chemical Degreasing of Kitchen Exhaust System

Grease accumulation inside kitchen exhaust systems is a serious fire risk and hygiene concern. Our chemical degreasing service uses industrial-grade, food-safe chemicals to dissolve and remove hardened grease from hoods, ducts, filters, and fans. The process includes inspection, chemical application, scrubbing, and rinsing—leaving your system clean and compliant. Regular degreasing improves airflow, reduces odor, and ensures your kitchen meets SFA and FSSD standards. We recommend scheduled degreasing every 3 to 6 months depending on cooking volume.

Fabrication and Installation of Stainless Steel / Aluminum Kitchen Exhaust Hood

We custom-fabricate exhaust hoods using high-quality stainless steel or aluminum, designed to suit your kitchen’s layout and cooking equipment. Our hoods are built to capture smoke, steam, and grease effectively, and include integrated grease filters, lighting options, and duct connectors. The materials used are corrosion-resistant, easy to clean, and durable under high-temperature conditions. Our installation team ensures precise alignment, secure mounting, and proper airflow integration with your exhaust system.

Wet Chemical Suppression Systems

Our wet chemical fire suppression systems are designed to protect commercial kitchens from fire hazards. These systems automatically detect high heat or flames and release a wet chemical agent that cools the fire and prevents re-ignition. Ideal for cooking areas with fryers, grills, and open flames, our suppression systems are installed in compliance with FSSD guidelines. We provide complete service including system design, installation, testing, and certification. Regular inspections and maintenance ensure the system remains fully functional and ready to respond in case of emergency.

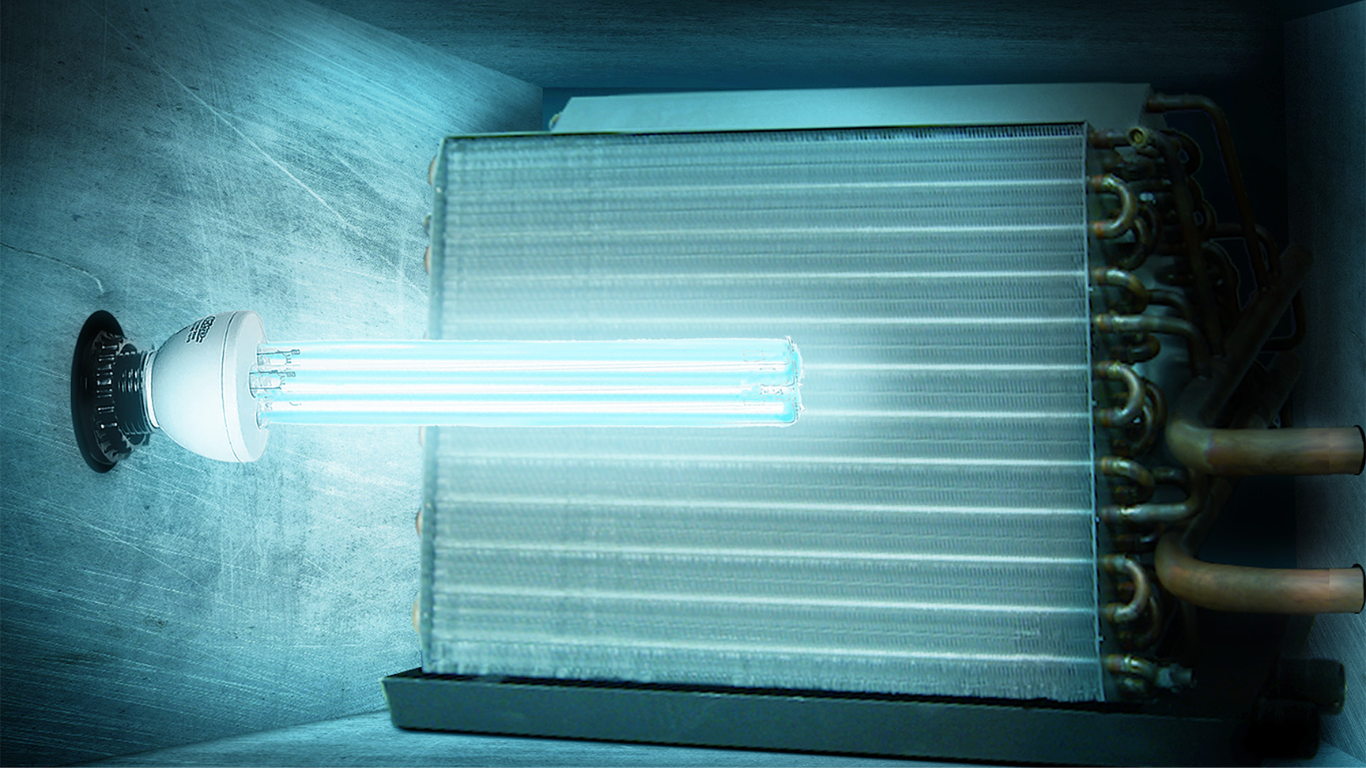

Electrostatic Air Cleaners & UV-C Emitters

We offer advanced air purification solutions that combine electrostatic filtration with UV-C technology. Electrostatic air cleaners capture fine grease particles, smoke, and airborne contaminants using high-voltage filtration. UV-C emitters neutralize bacteria, viruses, and odors, improving air hygiene and reducing health risks. These systems are ideal for kitchens with high smoke output or limited ventilation. Our team handles installation, calibration, and routine maintenance to ensure consistent performance and compliance with air quality standards.

Kitchen Exhaust Fans & Variable Speed Drives (VSD)

We supply and install high-performance kitchen exhaust fans designed for continuous operation in demanding environments. Our fans are energy-efficient, low-noise, and built to handle high grease and heat loads. When paired with Variable Speed Drives (VSD), the fans offer adjustable airflow control based on cooking intensity. This helps reduce energy consumption, minimize noise, and extend equipment life. We ensure proper sizing, mounting, and electrical integration for seamless operation.

Fabrication of Electrical Control Panels

We design and fabricate custom electrical control panels for kitchen exhaust systems, fire suppression units, and lighting. Each panel is built to meet Singapore’s electrical safety standards and includes features such as overload protection, emergency shut-off, programmable timers, and automation options. Our panels are tailored to your kitchen’s layout and operational needs, allowing centralized control of ventilation and safety systems. We also provide installation, testing, and ongoing support.

Submissions to FSSD (Fire Safety & Shelter Department)

Navigating fire safety regulations can be complex and time-consuming. We assist clients by preparing and submitting all required documents to the Fire Safety & Shelter Department (FSSD) for kitchen exhaust systems, fire suppression units, and ventilation setups. Our team ensures that your system meets all fire code requirements and helps you obtain timely approval. We also provide follow-up support for inspections, compliance updates, and renewal submissions. With our expertise, you can focus on running your kitchen while we handle the paperwork.